A comprehensive portfolio of hard facing alloys using the latest application technology over a diverse range of industrial applications.

Hardfacing Spray Powders

There are 2 basic types of powder:

- Base powders with a hardness scale of 20 – 60 Hrc

- Ready mixed powders with cast tungsten carbide particles 40 - 80µ to give increased wear resistance

- These are atomised Nickel alloy powders containing Nickel, Chromium, Boron, and Silicon.

- Boron and Silicon are good fixing elements.

- Hardness values are dependent upon the Chromium-Boron-Silicon content.

Flexible Electrode – Hardfacing Cord

Cord composition:

- Central metal core : 1.2mm diameter Nickel wire.

- Matrix : Nickel based powder - hardness value 40Hrc (content 35%).

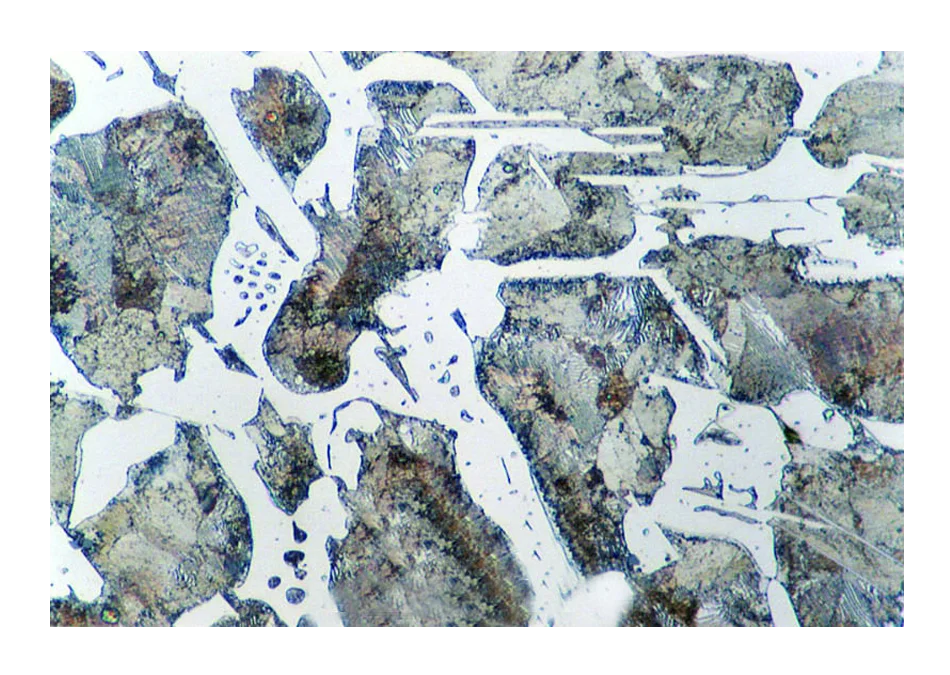

- Cast or Spherical tungsten carbide particles – with grains of varying shapes and sizes – hardness value 2000 – 3000HV (content 65%)

Two Types of TENROCK™

- Tenrock 2000 – Cord containing cast tungsten carbide : Good for wear resistance.

- Tenrock 3000 – Cord containing spherical tungsten carbide : Increased shock / impact resistance.

Weld Properties

- Dense homogeneous coating from 2 – 10mm thickness.

- High wear resistance.

- Good corrosion resistance.

- Average density 13.6 kg/dm3.

- Easily applied by any competent welder.

TENROCK™ Transformation

TENROCK™ has been designed, developed and adapted to cope with diverse operating conditions and enables longer production runs and minimise plant downtime.